How Mousepads Are Made: From Start to Finish

Ever wondered how mousepads is made? At Mousepad Warehouse, we take pride in creating high-quality, durable mousepads that are built to perform and last. Here’s an inside look at the process:

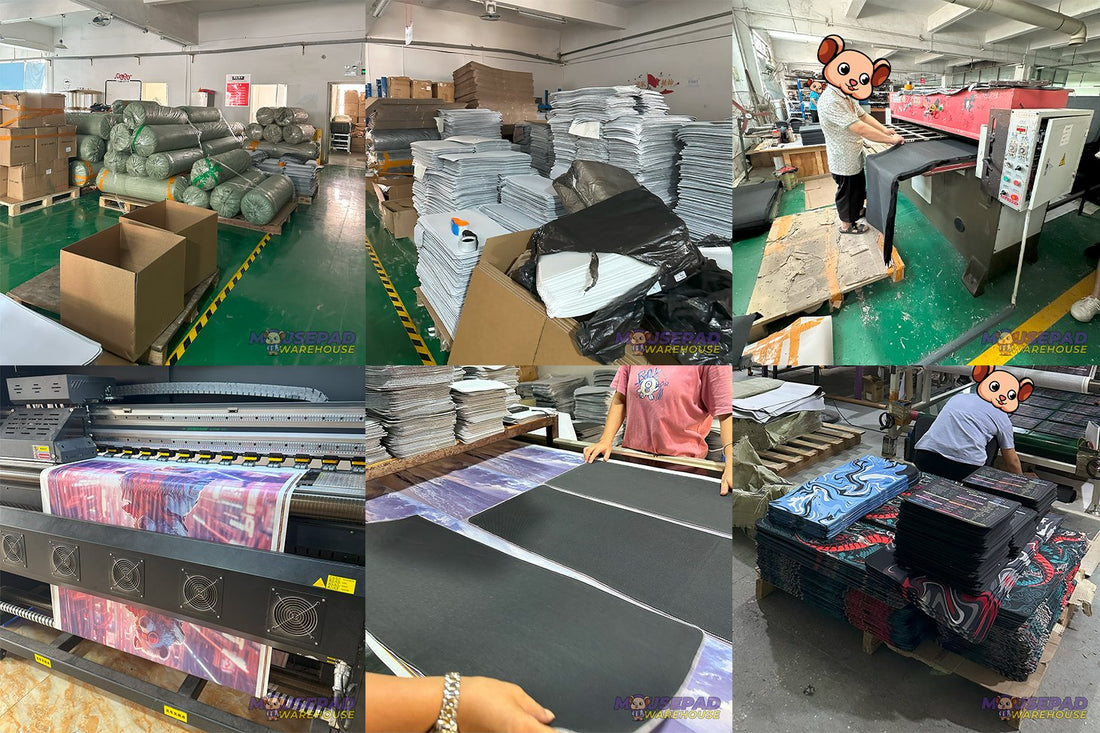

1. Sourcing Premium Raw Materials

It all starts with quality materials. We source top-grade cloth, non-slip rubber, and sublimation paper to ensure vibrant colors, durability, and smooth performance. With enough inventory for 12 months, we’re always ready to meet demand.

2. Cutting to Size

After joining the cloth to the rubber base, the material is precision-cut to our various mousepad sizes, from compact desk mats to large gaming pads, ensuring the perfect fit for any setup.

3. Prepping Mousepad Blanks

We stock pallets of blank mousepads, both stitched and non-stitched, ready to be customized. This allows us to print and ship your order as quickly as possible.

4. High-Quality Printing

Your chosen design is printed onto heat transfer paper using a sublimation process. For the best results, we recommend high-resolution images (300 DPI, CMYK).

5. Heat Transfer Process

The magic happens here! Blank mousepads are placed over the printed design and passed through a heat transfer machine, permanently bonding the vibrant image to the cloth.

6. Quality Check Before Shipping

Every mousepad undergoes a thorough quality check to ensure it meets our high standards. Only the best make it to the packaging and shipping stage.

From raw materials to your desk, every step is carefully designed to create a mousepad that’s as functional as it is stylish. Explore our collection or customize your own today to see the quality firsthand!